With offices and a strong network of consultants in Europe, the Middle East, South America, and Asia, USSEC continues to navigate the current challenges and continues its work to retain U.S. Soy’s customers when the COVID-19 crisis ends. During these uncertain times , the U.S. soy industry remains committed to supporting soy customers by transferring quality knowledge to improve efficiency, while also planting the seeds for future growth.

As one of the world’s leading and largest organizations in the animal feed industry, USSEC brings together U.S. soy customers, people, cultures, and ideas through organized activities organized to develop sustainable and efficient feed and animal production. From this perspective, the recent “Applied Feed Manufacturing and Animal Nutrition” virtual conference organized by USSEC Europe proved to be a resounding success and an interesting experience for speakers, participants, and organizers.

USSEC held a two-day online training for feed mill managers, nutritionists and quality control managers from across southeast Europe and around the globe. More than 200 feed mills from 59 countries on 4 continents participated in the virtual event; researchers and academia from Europe, Canada, and the United States were present as well. The event illustrates how the powerful message of U.S. Soy can be delivered through virtual events, by assembling and coordinating the USSEC team located in different countries of the world. These kinds of technical programs are indicative of USSEC’s ability, in cooperation with high profile subject matter experts, to improve the knowledge level among soy customers.

The core program was composed of lectures, practical demonstrations and panel discussions involving experts from Fortek Feed Laboratory and Norwegian Life Sciences University and drawn from the basic role of feed processing, to soy use in animal feeds and detailed practical demonstrations on feed mixing, conditioning, and pelleting. In addition to the training materials developed long in advance by the speakers, practical demonstrations were video-recorded and aired during the virtual event. Thanks to Dejan Dragan Miladinovic, the head of Fortek, the virtual event turned into a dynamic meeting, with a enthusiastic attendance generating a high level of interaction with the speakers.

the head of the The FôrTek Feed Technology Lab from Norwegian Life Sciences University

The open discussion session dedicated to the soybean meal physical characteristics, inclusion rates in different feeds and impact on pellet quality and pellet mill production rate involved speakers and conference participants.

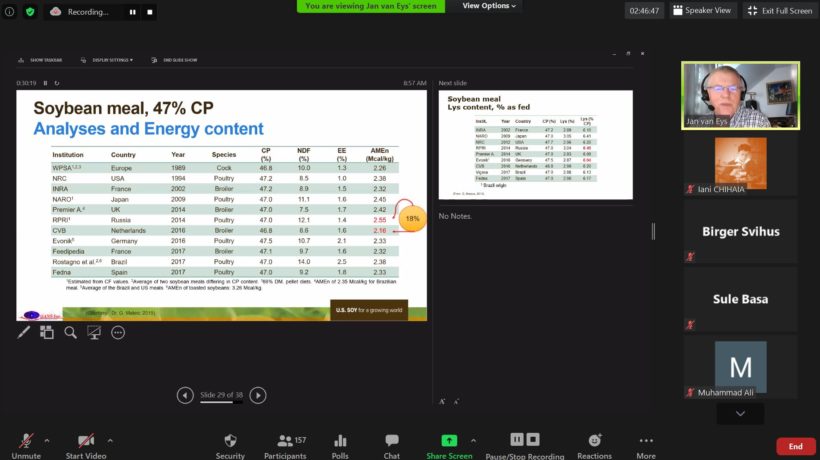

USSEC consultant Dr. van Eys emphasized, “Soybean meal has, on average, a particle size between 800 to 900 microns and the more uniform the particle size, the better for the raw material flowability and amino acids digestibility. This is particularly true in the case of U.S. soybean meal and feed manufacturers should use soybean meal as it is received from the oilseeds crushing plants, without further grinding because it is sufficient in particle size. However, in the case of other origin soybean meals, further grinding is needed, and this might have an important economic impact on the cost of production and increase in times because of routine maintenance such as turning hammers, changing hammer mills’ screens, and adjusting the gap between rolls and regrooving rolls.”

Dr. Birger Svihus from Norwegian Life Science University discussed the chemical changes with nutritional consequences due to conditioning and pelleting processes and focused on heat and moisture effect on proteins and the effect on nutritional value, especially in the case of Maillard reaction occurrence.

“Due to the heat applied during conditioning and pelleting, some chemical alterations may take place. Proteins are to some extent denatured, and this will potentially improve nutritional value through inactivation of proteinous antinutrients, although it may contribute negatively through inactivation of exogenous enzymes. However, the feed manufactures have to carefully monitor the heat treatments applied to feeds because Maillard reaction reduces amino acid digestibility by combining amino acids with sugars to produce biologically unavailable compounds and some vitamins may be destroyed during the pelleting process, and viscosity of soluble fibers may increase,” Dr. Svihus accentuated, knowing that soybean meal is a sensitive raw material to overprocessing.

The success of the event may be explained by the fact that over 200 participants were constantly active online for two consecutive days, for five hours per day, taking advantage of the opportunity to blog and ask questions live. The speakers kept answering questions from participants for several days after the event and online networking is still ongoing.

Dr. Iani Chihaia, USSEC Consultant for South East Europe and the initiator of the activity stated, “The resounding success of the USSEC Europe virtual event committed U.S. soy customers to dialogue and created the base for a global feed manufactures online community. We are incredibly pleased with what we learned from the USSEC Applied Feed Manufacturing and Animal Nutrition virtual conference and very much look forward to building on this success with upcoming events.

“With physical meetings and business travel being canceled, postponed, or restricted as a result of the ongoing pandemic, we are pleased to be able to give something back to U.S. soy customers during these circumstances. USSEC should look with fresh eyes on the use of digitization and social media to expand education opportunities, to create entry points for engagement with the U.S. soy customers. Social media enables us to tell the U.S. soy story to our customers and followers interested in USSEC experiences. I would like to thank the U.S. soy industry for supporting our activities. To my USSEC colleagues, to our speakers, and to all of our participants, I look forward to virtually meeting them again, soon,” Dr. Chihaia wrapped up.