Romanian Customers Utilize USSEC Training in NIR Technology

- Category:

- Animal Utilization

- General News

Quality control and the rapid assessment of raw materials and compound feed is crucial for the modern feed industry. To make decisions, nutritionists and purchasing managers need to know how ingredient variability, processing treatment, and other factors lead to a large variation in final product quality, eventually impacting profitability. Accurate and reliable composition analysis of raw materials and compound feeds is important for feed and livestock industry.

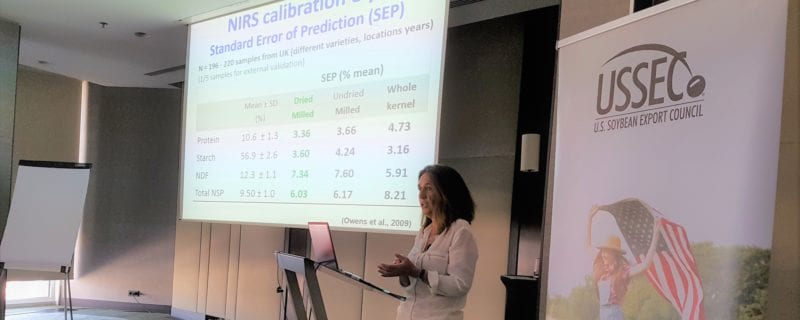

In answer to the willingness of U.S. soy customers to improve soybean meal analysis, for the past few years, USSEC Europe has organized several trainings focused on near infrared (NIR), to support customers from several European countries in better understanding on how NIR technology will help nutritionists and quality control managers to improve ability in recognizing the value of U.S. Soy.

Under the coordination of Dr. Gonzalo Mateos, professor at the Universidad Politécnica de Madrid, Universitat Autònoma de Barcelona, and Universidad de Córdoba, implemented NIR training programs for participants from South European countries and followed up with a one-on-one workshop in Romania.

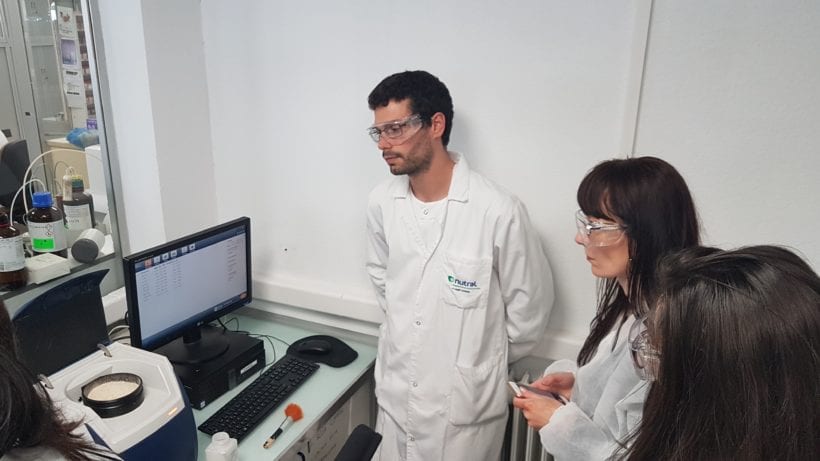

“Over 75 percent of the soybean meal used at this stage is analyzed by NIR and is today a standard process management tool for most of the feed mills in Romania. Besides rapidity, the NIR method brings repeatability and transparency that allows to make better and faster decisions and identify areas for improvements,” stated USSEC regional consultant Dr. Iani Chihaia at the USSEC Quality Control Training organized in April 2019, in Bucharest, Romania. “Our customers succeeded in properly implementing knowledge gained, thanks to USSEC’s educational programs, and created robust calibrations for many different origin soybean meals over a very wide composition range. This is an important achievement, especially in the case of the equipment suppliers that do not provide any calibrations for their NIR instruments. Meantime, better calibration could increase the understanding of soybean meal value and ultimately easily identify the reliable suppliers.”

In June, a two-day training was organized at the University of Cordoba, Spain. The agenda of the event focused on various applications in animal feed and the technology itself. The trainees were shown many kinds of equipment and data utilization procedures ; they also learned about what will be coming in NIR in the future, such as the role of NIR in the massive sampling of bulk products and various other uses.

Quality control representatives from Romania attended the event and showed great interest in learning more about how to properly interpret the statistic results from NIR analysis and how to implement qualitative analysis of soybean meals of different origins.

The USSEC NIR trainings proved to be excellent opportunities for the attendees to refresh their knowledge and understand how NIR should be better used in order to get more value from U.S. soybean meal and how to detect potential adulteration of this valuable ingredient.