Soybean meal is the primary source of protein for the feed industry worldwide, and an important protein source in livestock, poultry, and aquaculture diets. Among protein sources of plant origin, soybeans have the highest crude protein content, a balanced amino acid profile, and a high level of digestibility. Soybean meal is the standard against which other protein sources are compared. Understanding more about the chemical composition, protein quality, and nutritive value of commercial soybean meals enables us to better determine important agricultural outcomes. A meta-analytical study released this year reinforces U.S. Soy’s reputation for being a global leader in quality and nutrient density and USSEC’s technical assistance helps customers to learn more about soy quality.

“Novelties and Key Knowledge Gaps in Soy Feed Ingredients Quality Control,” USSEC’s recent online course, sought to increase customer awareness on soy quality and differences between soybean and meal origins. The event, which reached participants in 40 countries, reviewed current analysis methods for soy protein ingredients and discussed recent advances in Soy Quality Control and the most recent soy research.

Soy ingredient quality is the result of many factors, including bean variety, origin, processing and storage. Although soybeans and soybean meal are some of the most homogeneous ingredients used in feed manufacturing, quality is variable and a large number of factors can affect quality, especially in terms of protein and amino acid digestibility. Soy processors and their customers in the animal feed industry need reliable, rapid and cost-efficient methods to control the quality of their soy ingredients.

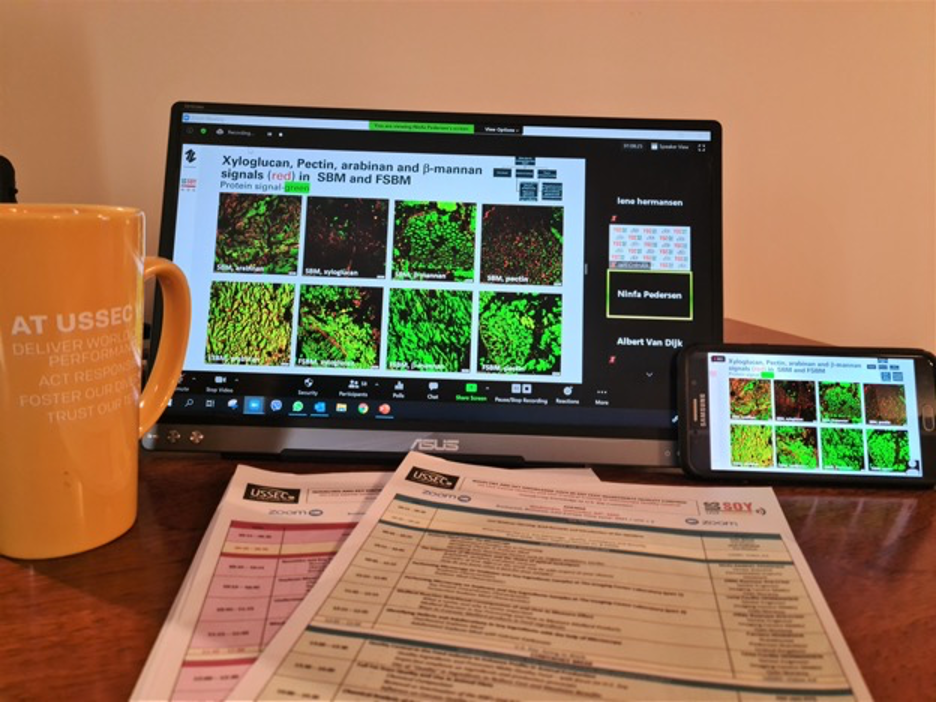

Experts in Animal Nutrition, Quality Control, Microscopy and Enzymology introduced the latest developments in quality control, providing participants with inspired thinking to address quality control of soy products in a new way to align with the latest trends in animal nutrition and capture the U.S. Soy Advantage.

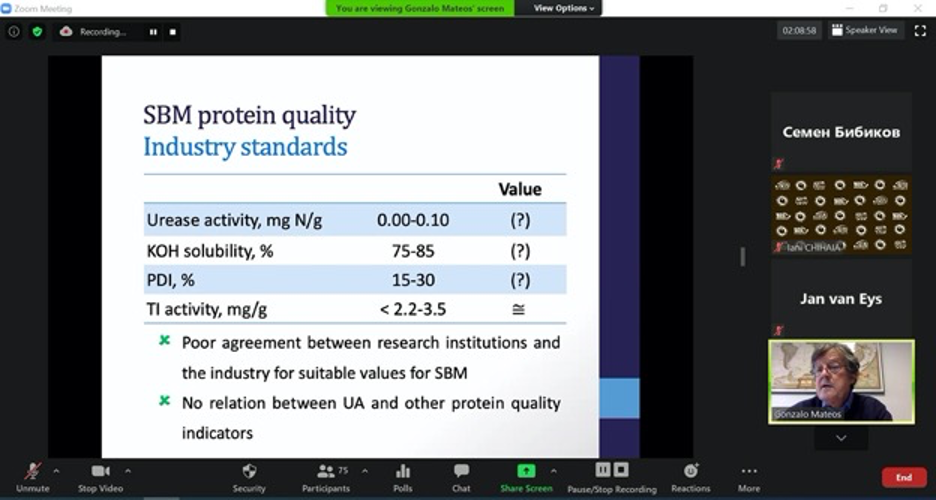

The speakers explained that one of the main challenges during the soybean meal manufacturing process is temperature control, which is critical for deactivation of the anti-nutritional factors present in raw soybeans. To get a product with optimum nutritional values, the exposition of soybean flakes to optimum heat treatment is crucial. In case of the application of excessive heat, a Maillard reaction occurs and soybean meal with less soluble and digestible protein will be obtained. Therefore, quality control of soybean meal is very important, and the proper implementation of analysis methods requires considerable work.

Questions raised during the live sessions focused on several topics. At the request of the audience, the speakers reviewed the available test to be implemented under commercial conditions and concluded that the PDI with its high accuracy and low skill requirements is probably the most suited to effectively and rapidly measure protein quality in a commercial feed mill or crushing plant. They pointed out however, that like the urease index, PDI is a test best suited to detect underheating while KOH solubility of protein is better suited to detect overheating. A combination of both tests is recommended as the most effective quality control measure. A rigorous application of both tests should improve formulas and will lead to better supplier segregation.

Suppliers are likely to incorporate such tests or the information in their customer service. These tests do, however, require a minimum amount of equipment - a plant laboratory, skill, and time, and this is not always available especially in smaller operations. In that case, the rapid urease test still provides a good alternative and assures minimum quality standards. It leaves little doubt that a rigorous application of these tests will result in better performing diets and potential cost savings.

“Through recent events dedicated to the quality of soy products, USSEC has encouraged those already working in the soy quality control area, either to explore or contribute to the development of novel approaches to understand the soy ingredient quality,” concluded Dr. Iani Chihaia, USSEC Country Representative – Greater Europe, Romania, who hosted the event.

“In addition to refreshing and reinforcing the importance of quality control for soy products, the presentations made by the speakers helped to clarify the needs of the feed industry in terms of updating the quality control programs and stimulated the end-users to pay more attention on differentiating between soy origin to take the advantage of U.S. Soy’s availability and quality.”