USSEC Organizes On-Site Training in Spain for European Customers

- Category:

- Animal Utilization

- General News

In an effort to assist continuous knowledge and skills improvement for U.S. Soy customers from the European countries of Russia, Poland, Romania, Hungary, Bulgaria, and Turkey, USSEC organized an on-site training at two relevant integrated companies, Copiso Coop and DAGU Feed Mill, located near Madrid, Spain.

USSEC consultant Dr. Mateos Gonzalo coordinated the event, which offered participants a broader view of the manufacturing, quality standards, and good practices in Spain during the last week of March. Spain is the second largest feed compound producer in the EU 27, with an annual production of 31 million tons of compound feed and is also one of the top U.S. Soy customers in the region.

The on-site feed mill training has important merits, including unique learning opportunities for both participants and hosts. All participants had the chance to interact at a higher level and bring theoretical discussions and topics to commercial production situations, making topics of interest more tangible and easier to understand.

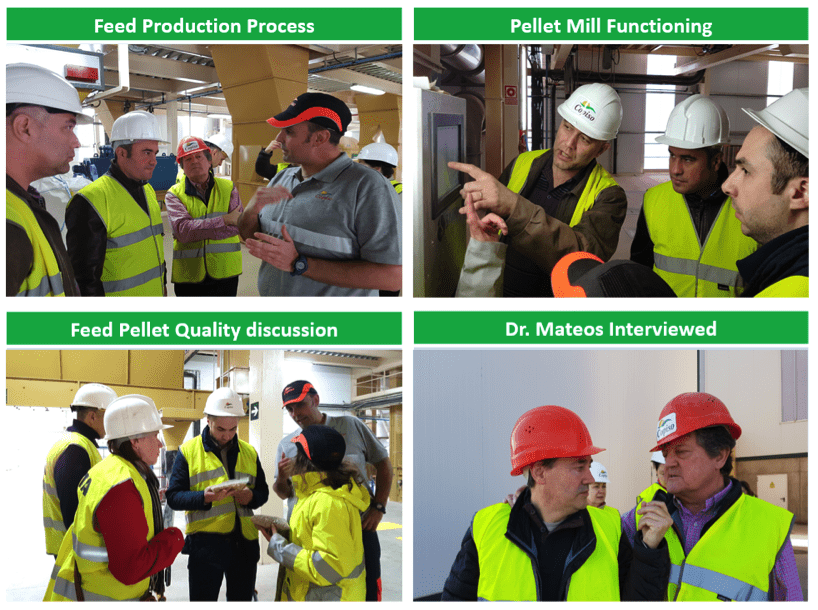

The first company visited by the team of USSEC trainees was Copiso Feed Mill in Valcobra, part of a fast-growing cooperative from the Soria area in Spain. Copiso offers fertilizers, grains drying, veterinary and transportation services, compound feed and other products to its members, as well as warehousing, swine insemination centers, and related services. The cooperative was founded 50 years ago and its organizational structure is an excellent model for the growing Eastern European agriculture.

DAGU Feed Mill was the second integrator to open its gates for the USSEC training. DAGU is a leader in the egg sector and one of the first operators in the egg export trade from Spain. The company has acquired experience over the last 50 years working in the poultry-farming sector, always maintaining a leadership position. The company has modern equipment and technologies in all production process points: raw materials reception, feed manufacturing, egg production, grading, packing, and processing. All the processes at DAGU, for both the production and marketing of the eggs and egg products are strictly controlled by their own laboratory, which has state of the art technology and complies with the strictest standards of control, thus offering our customers a top quality product.

The field visits at the Copiso Cooperative and Dagu Feed Mills were perfect opportunities for the participants to visit companies to exchange information about the current practices in raw materials quality control systems and feed additives usage in different European countries. Besides learning about the latest advances in raw materials quality, students had the opportunity to understand the Spanish experience in feed quality control under EU laws and regulations and near future challenges in feed additives use.

Learning from the experience of integrated companies from the Soria and Guadalajara areas was highly interesting. Spain is perhaps one of the most noteworthy markets from the point of view of industry organization. The business model of cooperatives and integrated companies has some particularities in Spain: poultry and pork meat producers are acting more like partners with feed manufacturers, meat processing, marketing, and distributors. Animal farmers receive all the feed, drugs, and vet services from the integrator, based on prices agreed between the two parties. This gives the freedom to feed manufacturers to adapt the feed formulation based on the raw materials availability and price in the market.

With eight ports across the Iberian Peninsula, Spain has significant advantages in importing feed ingredients and exporting meat. The country’s strategic location gives the feed and livestock industries the ability to reach any market from Europe and Asia.