Polish Poultry, Swine Feed Industries Customers Benefit from USSEC’s Feed Manufacturing Technology Service Tour

- Category:

- Animal Utilization

- General News

Editor’s note: The event featured in this story took place prior to the USSEC travel ban due to COVID-19.

Over the past few years, USSEC has provided technical support to improve livestock feed manufacturing technology through various conferences and seminars offered in Poland and the entire North-East European sub-region. The positive response of the professional audience encouraged USSEC to plan an activity aiming at providing unbiased professional assistance to poultry and swine feed the manufacturer to help improve their manufacturing technology in 2020.

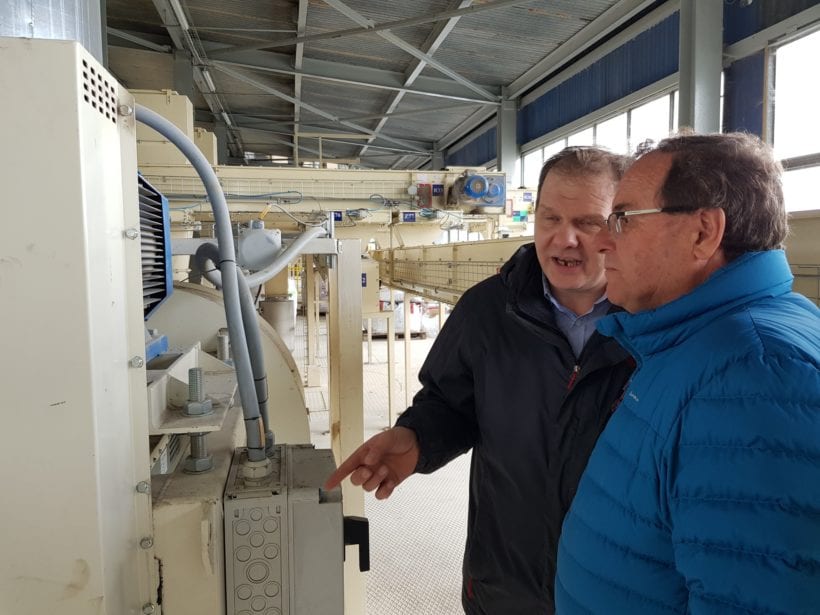

Late this winter, USSEC consultant Juan Acedo Rico, Acedo & Associates, Spain, joined Jerzy Kosieradzki, USSEC Technical Director North-East Europe, to visit customers in western Poland for what they referred to as a service tour.

Beginning in the southeastern city of Wrocław, Lower Silesia Region, they worked with Pasze Bios, a feed branch of a broiler and layer company owned by the Głowa family. A couple of years before, they had purchased an old abandoned large feed mill (Kochanowice) from Cargill and put it into operation. This effort was so successful that the company is already working three shifts, using almost 90 percent of its capacity, leading its owners and managers to look for ideas how to expand and improve production capacity.

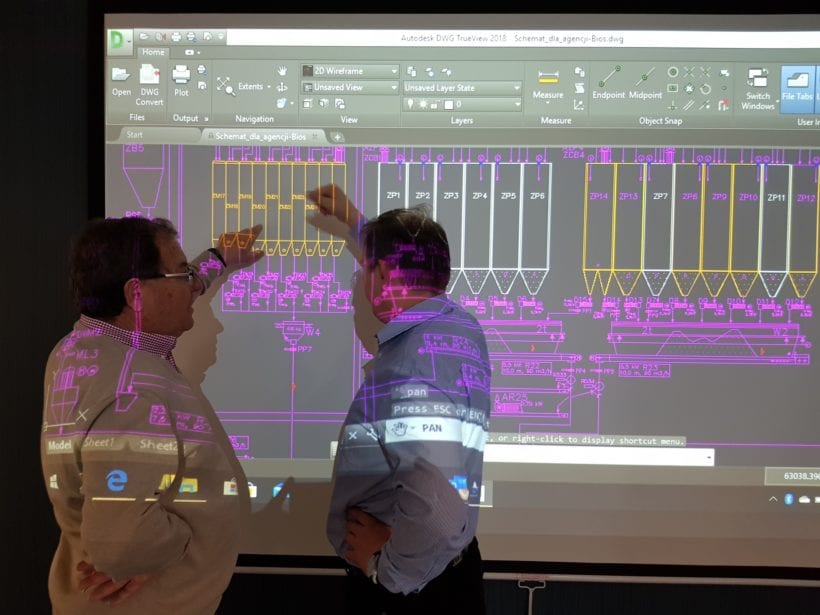

Mr. Acedo-Rico reviewed their technology and proposed expansion in two perspectives: short term and long term. He took two days to evaluate the mill from every angle, spending hours there and in the office to check the layout and determine how everything worked, before offering his advice. The company also shared and discussed an initial design of a large expansion project.

Blattin Polska in the Opole Region was another stop for USSEC. Major space concerns are a limiting factor at their original feed mill. Mr. Acedo-Rico toured the plant and discussed their production process, as well as scouting best options to improve their operations. He identified two major scenarios and explained them to Mr. Mirek, Managing Director and Co-Owner, and Ms. Szczachor, Nutritionist/Technologist.

The work with Tasomix, a large feed compounder, recently acquired by For Farmers, was completely different. Here, a bigger group met in the office, where Mr. Acedo-Rico provided answers and explanations to a full list of technical questions that had been sent to USSEC ahead of time. Thus, it was a tedious but rewarding workshop rather than a quick fix meeting, which truly helped the team to learn new things and/or reconfirm what they were already doing. Mr. Acedo-Rico toured their feed mill at Biskupice Ołoboczne, saying, “It could probably be one of the best feed mills in Netherlands; so close to the ideal.”

Neorol is a smaller family owned compounder that operates two feed mills, but Mr. Acedo-Rico’s work concentrated at the mill located in Chrzan in the Wielkopolska Region. Since the relationship between USSEC and Neorol had been rather limited before, the USSEC team had to explain soy markets and talk about USSEC activities around the world, particularly in Europe and Poland, before they could move to discussing feed manufacturing technology issues. Later they moved rather to Neorol’s issues in the area of feed production and quality and addressed them. This was USSEC’s first major activity at the company.

The Polish customers who worked with Mr. Acedo-Rico during the service tour were very pleased with his practical experience and approach to every challenge. Every company and each individual truly benefited from the consultant’s visits and USSEC projects.