In-Pond Raceway System (IPRS)

Smarter aquaculture starts here. Improving aquaculture pond productivity has been a challenge for freshwater fish farmers for decades, the In-Pond Raceway System (IPRS) provides a solution.

What is IPRS?

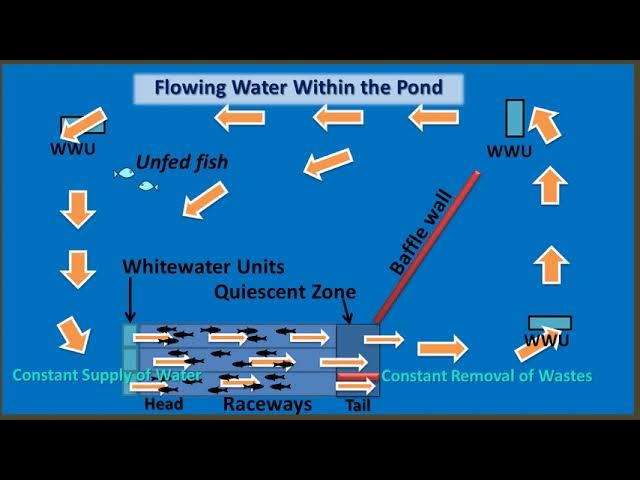

The In-Pond Raceway System (IPRS) is a modern aquaculture technology that enhances the productivity, efficiency and sustainability of aquaculture ponds. It merges the control of raceway systems with the practicality of static pond culture by confining fish to a raceway—an engineered, flow-through structure—within a larger pond. This creates a “river in a pond” effect where water circulates continuously, mimicking the oxygenation and waste-flushing functions of natural riverine systems.

Adoption of the In-Pond Raceway System has transformed the way producers manage space, stocking density, fish health and feeding across freshwater systems around the world.

Why IPRS Matters

While the In-Pond Raceway System has demonstrated tremendous potential, its success ultimately depends on strong technical management. IPRS isn’t a plug-and-play solution—it’s a tool that works best in the hands of well-trained operators who understand how to optimize the system from end to end. With the right oversight, producers can unlock measurable gains in efficiency, fish welfare and operational control.

When managed properly, IPRS can help farmers:

- Improve fish health and monitoring: Confined raceways make it easier to observe behavior, detect disease and treat fish promptly

- Reduce labor inputs: Feeding and mortality collection can be handled more quickly from a central point

- Minimize water usage: IPRS eliminates the need for regular water exchange—only seepage and evaporation losses need to be replenished

- Boost biosecurity: Targeted treatment and better confinement reduce risk of widespread outbreaks

- Enhance operational efficiency: Staggered stocking allows for consistent cash flow and flexible harvest scheduling

These benefits make IPRS an ideal solution for scaling up aquaculture pond operations while maintaining control over inputs and outputs.

What Species Work in IPRS?

The In-Pond Raceway System was originally designed for freshwater finfish species. It is most commonly used for:

Chinese carps

Largemouth bass

Tilapia

Channel catfish

Pangasius catfish

Some marine species—including barramundi, pompano, and Mediterranean seabass and seabream—have been cultured experimentally in IPRS systems, though less frequently. Each raceway is engineered to meet the biological needs of the species being farmed, and raceway stocking strategies can be tailored to optimize feed performance, health outcomes and harvest timing.

IPRS and Soy-Based Aquafeeds

Because fish in IPRS systems are confined at relatively high densities, the type and quality of feed used becomes even more important. High-quality, extruded diets are essential for optimal performance—and that’s where U.S. Soy plays a critical role.

In raceway technologies, soy-based aquafeeds offer several key advantages:

- A reliable alternative to fishmeal: Soybean meal and value-added soy products like protein concentrates (SPC) provide a highly digestible amino acid profile across species1,2.

- Environmental efficiency: Soy is considered a sustainable alternative to marine-derived aquafeed ingredients3, and U.S. Soy has a lower carbon footprint than soy from other origins4.

- Economic predictability: U.S. Soy provides a dependable and cost-effective ingredient amid fluctuating global markets.

Beyond sustainability and supply chain benefits, soy-based feeds also make strong financial sense for IPRS operations. Feed typically represents 50–70% of total production costs when growing market-ready fish5—making diet quality a critical factor in achieving profitability. Managers who invest in high-quality, nutritionally complete feeds consistently see better returns than those using cheaper, incomplete diets, especially in intensive systems like IPRS where there’s no margin for error.

In IPRS raceways, fish rely entirely on feed to meet 100% of their protein, fat, energy, vitamin, mineral, and micronutrient needs. That’s why soybean meal—thanks to its high protein content, digestibility, balanced amino acid profile, stable supply and reasonable cost1,6—has become one of the most widely used and cost-effective ingredients available for aquafeeds6.

Simply put: In IPRS systems, investing in better diets drives better outcomes. When profit margins are the goal, diet quality isn’t an area to cut corners—and soy-based feeds help you optimize both performance and profitability.

Should You Consider IPRS for Your Farm?

Candidates for IPRS adoption are encouraged to consider the following constraints. Each of the following critical criteria must be met to capture the benefits of IPRS and success, according to USSEC proven and recommended IPRS management guidelines.

- Existing or planned ponds must have sufficient water volume.

- The farm’s electrically powered components require a stable supply.

- The farm must have access to high quality fingerlings.

- The business must have access to sufficient capital.

- The success of the business and the performance of IPRS depends on carefully following the principles outlined above and further detailed in the IPRS Manual (linked below) to facilitate the enhanced efficiency and yields described.

- If the standards are followed, users should see the performance stated.

- Not following the correct standards and/or not understanding and following the principles will lead to reduced performance, impact profitability and increase the likelihood of business failure.

Access IPRS Planning Tools

Take a deep dive into USSEC’s resources for adopting IPRS, then download the IPRS Manual to explore design, stocking, feeding and maintenance practices in detail. The manual is updated as needed (last in 2022, next update planned for 2025).

3. https://www.sciencedirect.com/science/article/pii/S2451943X24000486?via%3Dihub

4. Mérieux NutriSciences | Blonk, Agri-footprint

5. https://www.fao.org/4/i1143e/i1143e.pdf

6. Dersjant-Li, Yueming. (2002). The use of soy protein in aquafeeds.