One Customer at a Time, USSEC Addresses Bottlenecks for Polish Feed Compounders

- Category:

- Contractor Reports

- General News

By Jerzy W. Kosieradzki, USSEC, Technical Director and North-East European Contractor

One of the most rewarding activities USSEC does in North-East Europe are “Poultry and Swine Feed Service Tours”, when internationally recognized experts in nutrition and/or manufacturing technology or quality assurance systems come to customers’ feed mills and provide assistance on procedures and competitiveness.

Pandemic travel restrictions have not stopped the council’s work with customers. The visits were just virtual instead of in-person, but still allow for much to be accomplished.

Recently, Juan Acedo-Rico, a Spanish expert in feed manufacturing technology and also a trained veterinarian and nutritionist, and I spent a week working with a number of Polish poultry integrators and feed compounders. Each meeting was very different and focused on different issues that were of importance to every company.

For instance, at BLATTIN-Polska, we met with two specialists as a follow-up to our previous in-person visit and discussed ways to improve their pelleting practices, especially of poultry diets, in an older mill that lacks space for additional equipment.

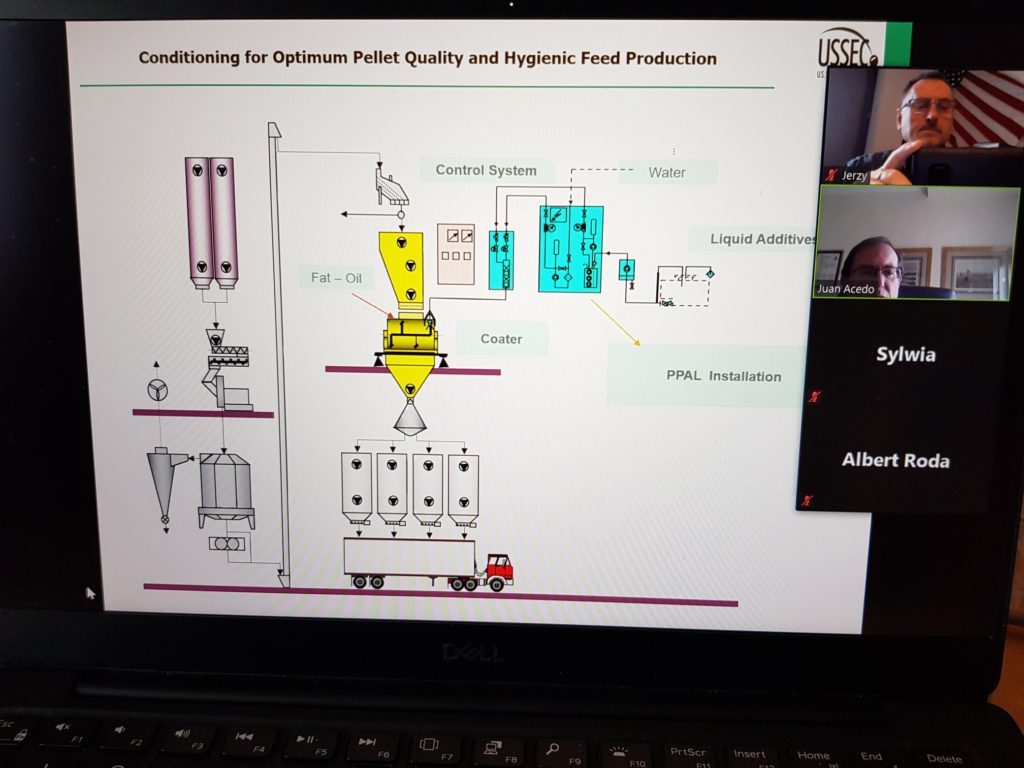

At NUTRIPOL, a feed branch of Poland’s largest turkey integrator, Juan coached them on improved conditioning and pelleting of turkey and pig feeds. As part of that, particle size required for optimal bird and animal digestive performance was thoroughly discussed.

The meeting with PIAST feed company was very different. First, a dozen of their specialists attended and a long list of prepared topics were discussed. Juan used many slides, drawings, tables and models to explain the experimental data and technological solutions that could help.

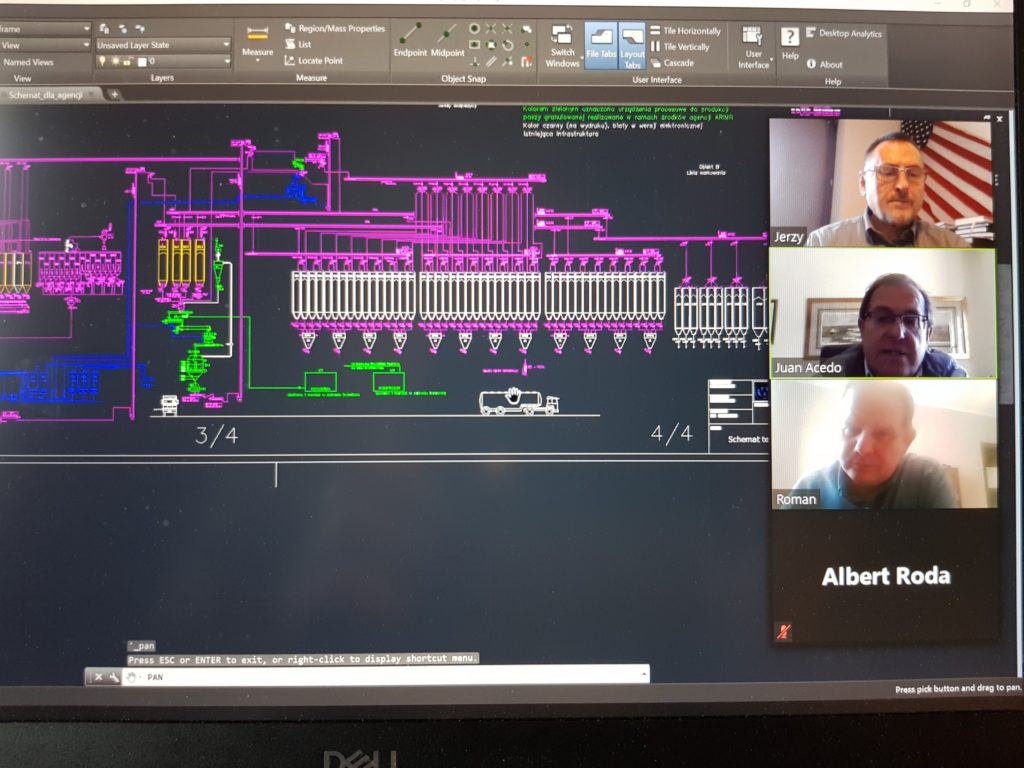

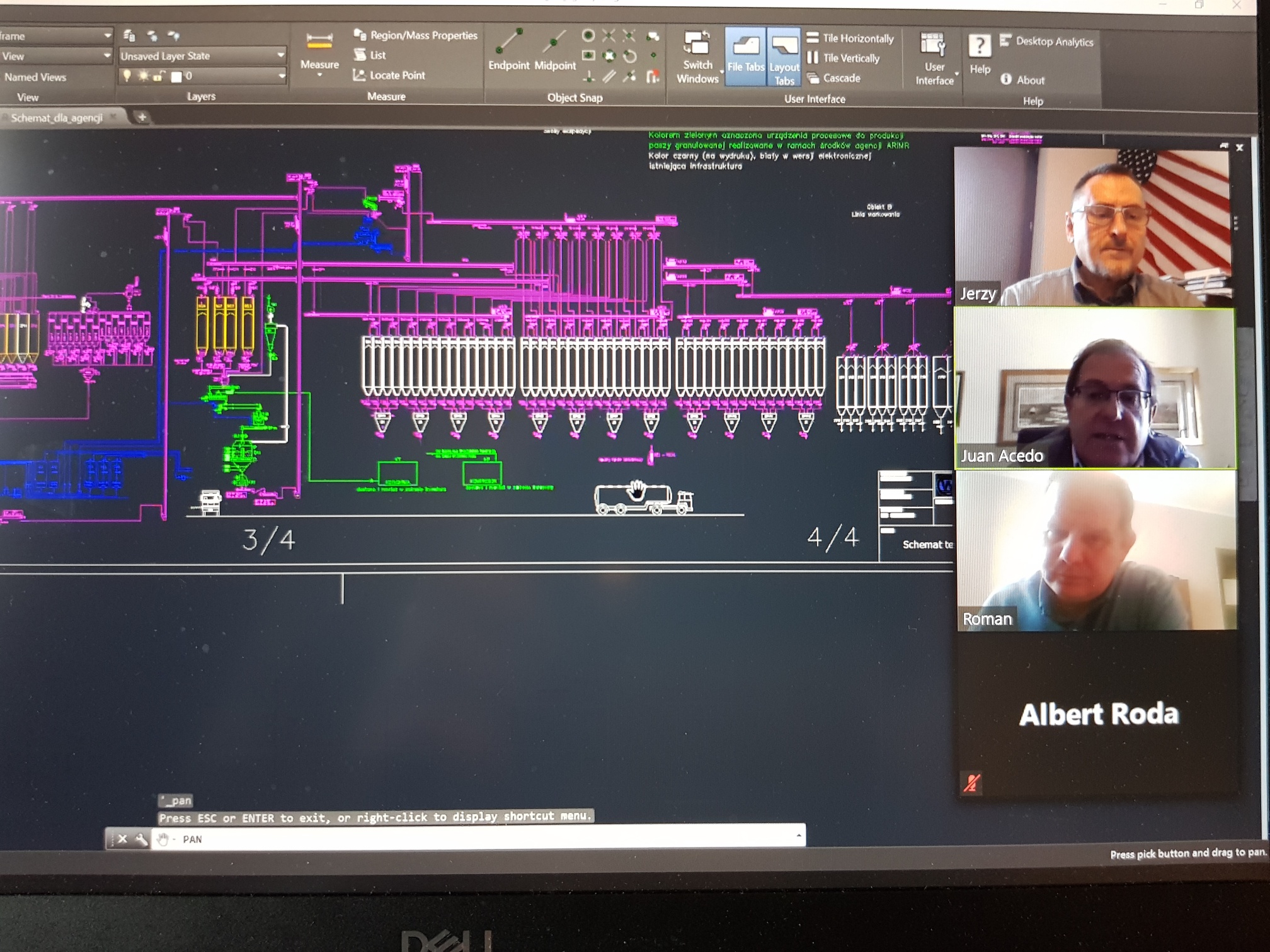

Meanwhile, Roman Kurzac, feed mill firector at PASZE BIOS, welcomed the USSEC team. Former help provided by Juan Acedo-Rico saved them from making some big mistakes in the modernization of an old mill they purchased. Plans for further improving their technology and quality as well as a substantial expansion of their production capacity set the table for USSEC’s time with them.

Working with individual companies helps to facilitate an open dialogue and creates an atmosphere that allows us to focus on the real bottlenecks our key customers experience and provide very practical help in improving their competitiveness.